Insulation fiberglass winding wire is a type of electrical wire that is commonly used in applications where high-temperature resistance and electrical insulation properties are required. Some of the features of insulation fiberglass winding wire include:

High-temperature resistance: Insulation fiberglass winding wire is capable of withstanding high temperatures, making it suitable for use in high-heat applications.

Electrical insulation: The fiberglass insulation provides excellent electrical insulation properties, making it ideal for use in electrical applications.

Chemical resistance: The fiberglass insulation is resistant to many chemicals, which helps to protect the wire from corrosion and other forms of damage.

High mechanical strength: The fiberglass reinforcement provides the wire with high mechanical strength, making it more resistant to breakage and other forms of damage.

Lightweight: Fiberglass is a lightweight material, which makes the wire easy to handle and install.

Non-magnetic: Fiberglass is a non-magnetic material, which makes the wire suitable for use in applications where magnetic interference must be minimized.

Low dielectric constant: The fiberglass insulation has a low dielectric constant, which means that it does not store a significant amount of electrical charge and does not produce significant capacitive coupling.

Resistant to moisture: The fiberglass insulation is resistant to moisture, which helps to prevent electrical leakage and other forms of damage.

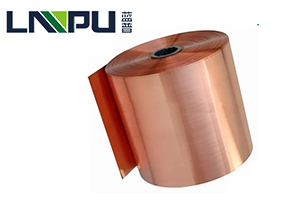

Insulation fiberglass winding wire is a type of electrical wire used in motors, transformers, and other electrical equipment. It is made by wrapping a copper wire with a layer of fiberglass insulation, which provides both electrical insulation and mechanical strength. This type of wire is commonly used in high-temperature applications, as it can withstand temperatures up to 200°C. The fiberglass insulation also provides good resistance to chemicals and moisture, making it ideal for use in harsh environments. Overall, insulation fiberglass winding wire is a reliable and durable choice for many electrical applications.