New Energy Vehicles (NEVs) have become increasingly popular due to their environmental friendliness and energy efficiency. As a result, the demand for NEV components has increased rapidly in recent years, including the enameled copper wire used in electric motors.

Enameled copper wire is a crucial component in NEVs as it is used to make the windings in the electric motors that power these vehicles. These motors convert electrical energy into mechanical energy to move the vehicle. The enameled copper wire used in these motors needs to be of high quality to ensure optimal performance and efficiency.

NEV enameled copper wire has several advantages over traditional copper wire. For one, it is coated with a layer of insulation material to prevent electrical shorts and ensure reliable operation. This insulation layer also helps to reduce the weight and size of the wire, making it more space-efficient and less bulky. Additionally, NEV enameled copper wire has lower electrical resistance, which reduces power loss and improves energy efficiency.

The production process for NEV enameled copper wire is also critical to its performance. The wire needs to be manufactured to precise specifications to ensure consistent quality and performance. The process involves several steps, including copper wire drawing, annealing, insulation coating, and curing. The final product must meet strict requirements for diameter, insulation thickness, and other electrical properties.

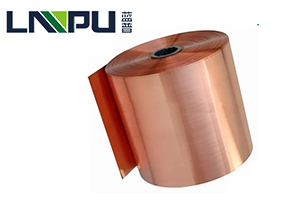

In recent years, the demand for NEV enameled copper wire has increased significantly due to the growing popularity of NEVs. As a result, many companies have invested in the development of advanced production technologies and materials to improve the performance and reliability of these wires. Go to see the new energy motor enameled flat copper wire.

There are also ongoing efforts to develop new materials for NEV enameled copper wire that are more environmentally friendly and sustainable. For example, some companies are experimenting with using recycled copper and insulation materials to reduce the environmental impact of manufacturing these wires.

In conclusion, NEV enameled copper wire is a critical component in the electric motors used in NEVs. Its high quality and reliability are essential to the performance and efficiency of these vehicles. As demand for NEVs continues to grow, the development of advanced technologies and materials for enameled copper wire will be critical to the continued success of the NEV industry.